The Water Industry Journal speaks to Jon Crowther of Sensor UK about why his company has made the move into designing leak detection systems for pipes and why their technology represents a breakthrough for the industry.

Jon and his team at Sensor have dedicated almost 30 years’ to developing leak location technology, much of which has been spent designing monitoring systems for geomembrane installations which are utilised in 44 countries around the world in numerous different industries, including the water sector.

What has perplexed Jon most in recent years, however, has been the frequency with which water industry colleagues have asked him whether he designed leak detection systems for pipes, so in late 2016, he set to work on a new project.

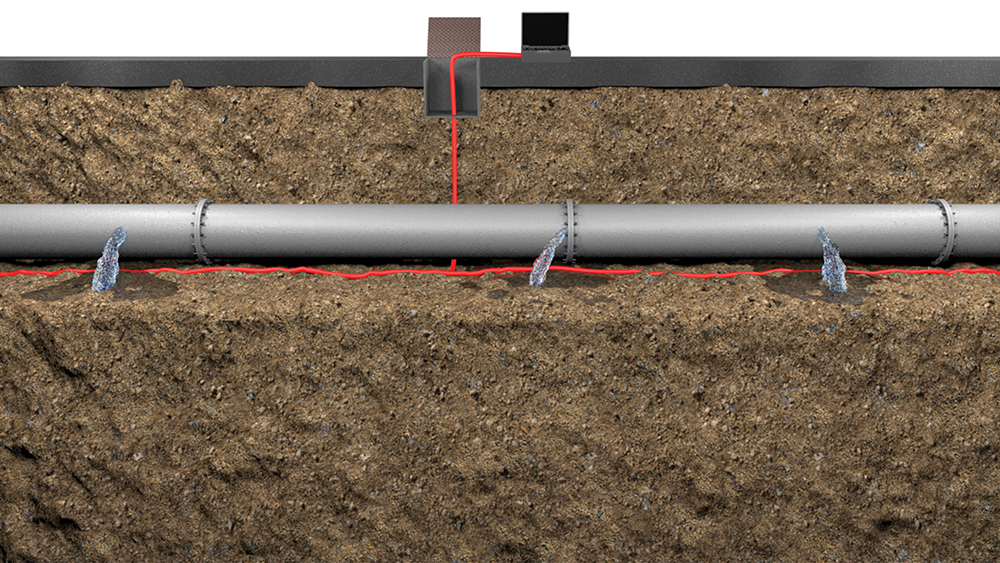

“We’ve developed a system in which an elongated sensor is placed next to the pipes and using electromagnetic measurements can detect elevated levels of relative dielectric permittivity (RDP) in the soil caused by localised leakage, the technology is very different to existing leak detection systems, which all focus on interactions with the pipe itself.”

“The sonic systems most often used by the industry have many limitations, they don’t work well in an urban setting where there is a high degree of background noise or with certain pipe materials, as such their finding don’t give definitive answers,” explains Jon.

“With our technology, we can pinpoint the location of a leak precisely and understand its gravity by measuring the permittivity of the soil, in normal wet soil the permittivity level is typically 10-20 RDP, whereas a leak presents with a permittivity over 85 RDP.”

“Our system provides a very cost-effective means of detecting leaks and each new pipe that goes into the ground without it is a lost opportunity, as installing this system works out at less than 2.5% of the cost of the pipe installation itself. LID is a complementary addition to existing leak monitoring technologies providing high-resolution leak location at around one linear metre, and in addition, as it also provides CAT 4 pipe location signals, its cost in real terms is therefore reduced further.”

“Recently after a presentation during a Q&A session someone said that there wasn’t a problem with newly installed polyethylene pipes. The photo is of a newly installed pipe [less than 6-months old]. A catastrophic failure occurred caused by an electrofusion collar that had been badly installed and was leaking. This caused erosion of the pipe itself until the pipe wall became thin enough to fail. The result was significant disruption and damage which we estimate cost the water supplier around £265,000.

“There are around five million of these welds completed each year in the UK even if the failure rate was a low as 0.25%, this implies a cost in the region of £3.25-billion which is interesting because this would be the approximate cost of deploying our technology on all of the UKs 350-thousand kilometres of water pipe (not just the new plastic ones).”

“Water companies face enough challenges with water shortages, climate change, legacy issues and regulatory pressure, and they are not going to go away. You want to be able to detect and resolve a leak before something catastrophic happens. Installing an effective leak detection system improves resilience, saving money and time.”

“We’ve now developed technology that works with all types of existing pipes too, with different options for existing metal pipes and for non-conductive pipes – leaving water companies better able to deal with the problems of an ageing infrastructure.”

“Whether you want to monitor new or existing pipes, a key benefit of this technology is that it can detect simultaneous leaks that are in very close proximity to each other, something other systems fail to do.”

“Our system provides 100% definitive results, quickly. Unaffected by noise, low pressure, or by pipe material and diameter. The simplicity of installation and the straightforward nature of the data output removes all complexity from pipe leak location.”

“Our technology represents the only truly new technology to monitor buried pipes in 20-years. It is the first time a leak detection system has been developed that works accurately with both existing and new pipe installations constructed of any material, as such it is a precise and versatile technology.”

Sensor is a company that has made a breakthrough in leak detection technology, but not only are they innovative, they also have a heart, as a percentage of profits from Sensor DDS® LID will be donated to WaterAid. What could be more important than helping people to access clean water even in the most difficult of environments?

“A step change is needed in the industry in terms of how leaks are detected. Our technology has the capacity to bring about that change, you just need to visit our test sites to see that’s the case. Where most existing leak detection systems infer, ours measure the leak with precision.

“Bringing about innovation in the water industry is extremely difficult, stepping away from the technology the industry has traditionally used is not something with which everyone feels comfortable. Individuals can’t be criticised for employing systems they’ve always used, but making a change and introducing something new is much more difficult.”

Here Jon lays down the gauntlet to both water and sewage companies, “to illustrate the benefits of our technology, we are willing to provide 300 metres of our sensing element and put it in a trench for you, then you can simulate leaks and we’ll show you where they are.”

Now all you have to do is pick up the gauntlet…

Email: jon@sensor.uk.com

www.sensor-uk.com