By Paul Barter,

Principal Process Engineer, Hydro International

The water industry loves innovation, provided it is “proven and reliable”. With tighter phosphorous consents coming into force, we will need ‘proven and reliable’ processes that meet these new limits. Can these processes also be innovative?

Proven and Reliable

Systems with proven wastewater phosphorus removal performance exist. One such system is a continuous vertical sand filter (DynaSand®) with additional chemical dosing to precipitate dissolved phosphates. DynaSand® has a proven track record worldwide, including at Växjö in Sweden, where it has been protecting lakes for the last 20 years.

The lake system in Växjö was receiving excessive phosphorus, causing algal blooms. The sewage treatment works was discharging around 1.9 tonnes of phosphorus per year, and nearby lakes were leaching 2.8 tonnes per year from phosphate-rich sediment. The maximum phosphorus the lake could safely absorb was just 1 tonne per year, so an 80% reduction was required.

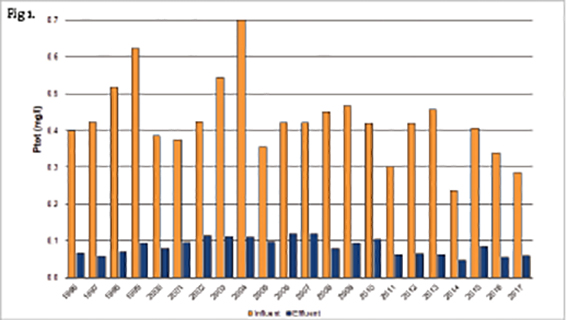

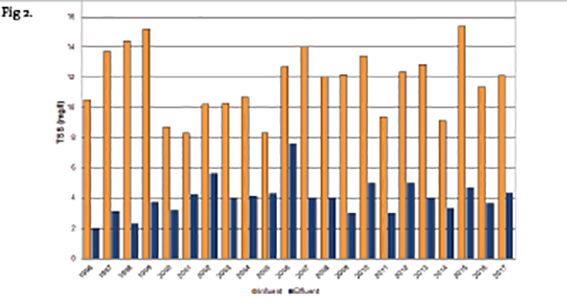

First, sediment was dredged from local lakes, then the sewage treatment works was upgraded and a 0.2 mg/l annual average phosphate discharge consent set. Pre-precipitation of phosphate was accomplished in primary settlement tanks, with post-precipitation using ferric sulfate at a new installation of 60 DynaSand® units. Over the last 20 years the plant bettered its 0.2 mg/l target, consistently operating at levels of about 0.1 mg/l (Fig 1). Outlet total suspended solids were in the range of 2 to 8 mg/l (Fig 2). This has improved water quality and restored the natural environmental balance.

What About Innovation?

That’s “proven and reliable” covered—what about innovation? There is often limited space available on sewage treatment works, so adding new process plant can be problematic. A system that combines processes, or an existing system that can be upgraded to remove additional substances, can make savings. DynaSand® filters combine phosphorous removal with ammonia or nitrate removal in a single stage.

Single Stage Phosphorus and Ammonia Removal

At Anglian Water’s Watton water recycling centre six DynaSand® Oxy filters were trialled. The study was part of the UKWIR CIP 2 scheme, and DynaSand® Oxy was the only technology trialled that combined phosphate and ammonia reduction. Phosphorus precipitation is implemented through load profile-based ferric dosing into the primary tanks and a small additional steady dose of ferric (5 mg/l) via a static mixer immediately upstream.

When the plant is operating optimally without other external factors causing an increase in the phosphorus load to the filters, the results demonstrate that an effluent total P concentration of 0.2 mg/l and ammonia concentration of 0.7 mg/l can be achieved.

Single Stage Phosphorus and Nitrate Removal

Denitrification is an important process where the receiving water body is particularly sensitive. It is often accomplished in the secondary treatment stage, but it can be necessary to remove nitrates as part of the tertiary process. This can be combined with phosphorous removal to produce a low-nutrient final effluent.

At Ratzeburg, Germany, a DynaSand® Deni system was installed to remove nitrates and phosphorous from the final effluent. Two chemical dosing systems were used: a ferric/alum dose to capture the phosphorous, and carbon to encourage bacterial growth for nitrate removal. The carbon source (methanol or ethanol) must be easily digestible to the bacteria, so it can be utilised quickly within the Dynasand® Deni, but it must be controlled because it adds BOD to the water. The growth of bacteria also adds to the solids loading on the filters, which must be considered, especially with the added solids from ferric dosing. The result, however, can be impressive, with very low phosphorous achieved, and total nitrogen levels of less than 10 mg/l.

A compact solution is disc filtration, with chemical precipitation along with flocculation, large phosphate rich floccs can be generated that are captured on the disc cloth. The high disc area allows high flow volumes in a small footprint. In Pietersaari, Finland, two DynaDisc® filters were installed which deliver phosphorus levels below 0.1 mg/l, with low solids.

The DynaSand® and DynaDisc® technologies show excellent long-term phosphorous removal, coupled with innovative additional pollutant removal in a single stage, allowing TSS, BOD, phosphorus and ammonia/nitrates to be removed from wastewater, improving water quality, protecting biodiversity and looking after the planet for future generations.

For more information on our wastewater phosphorus removal technologies visit:

hydro-int.com/hydro-p-removal