The Trant Group is pleased to announce the launch of Te-Tech Process Solutions. Building on Trant’s success as an EPC contractor in the water industry, the new company will be providing innovative products for water and wastewater treatment using advanced process technologies.

Te-Tech’s products are designed, manufactured and assembled off-site for rapid delivery, installation and commissioning. With in-house capability including process, mechanical and electrical design, digital engineering, operational optimisation and real-time control, Te-Tech has the flexibility to engineer bespoke systems from standard packages to meet the exacting needs of clients in the municipal, industrial and commercial water and wastewater sectors. Business Development Director, Mike Froom, says “Our strategic partnership with Austrian environmental engineering group SFC Umwelttechnik allows us to offer some novel technologies including advanced biological treatment, ultrafiltration, reverse osmosis and membrane bioreactors.”

To address key AMP 7 demands, Te-Tech has introduced te-cycTM cyclic activated sludge, a technology well suited for wastewater treatment works required to meet 1 mg/l P phosphorus residuals without chemical dosing. “The process achieves 0.3 mg/l P with a small dose of chemicals”, says Froom, “and 0.1 mg/l P with the addition of tertiary filtration.” The process is an enhanced sequencing batch reactor (SBR), where primary treatment, secondary biological treatment and tertiary settling are combined in a single process step.

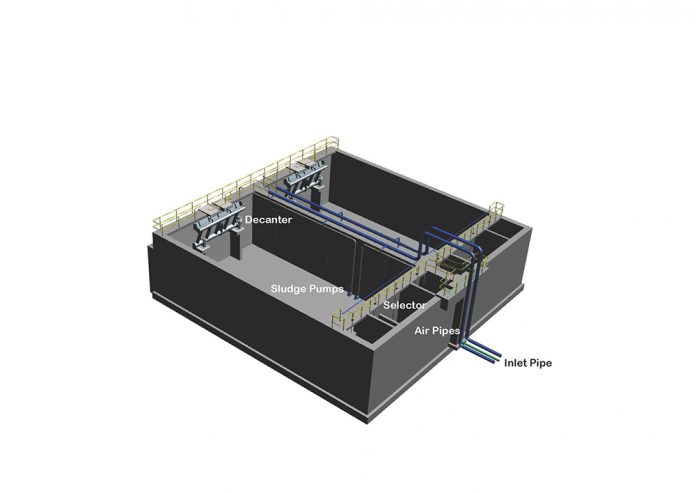

The te-cycTM is configured with two or more batch tanks installed in parallel with their sequences out of phase with each other allowing for a continuous flow through the system . Therefore, the te-cycTM can be regarded as a cyclic activated sludge process. Unlike traditional SBR systems, no upstream buffer tank is required for the system, which ultimately reduces the overall site footprint by approximately 50% compared to conventional continuous flow technologies. The unique features of te-cycTM include simultaneous nitrification/denitrification during the aeration phase and the selector zone for biomass conditioning, which distinguish the process from other traditional SBR type processes.

The anaerobic selector zone and internal recycle of the te-cycTM system allows for the formation of so-called “macroflocs” in which extracellular polymeric substances (EPS) produced by the floc-forming microorganisms under stress conditions act as a “glue” between them. They also provide perfect conditions for the growth of polyphosphate accumulating organisms (PAOs). These organisms release polyphosphates contained within them in the selector zone and then take up a greater amount of phosphate from the surrounding bulk liquor within the aerated zone. The phosphate-rich organisms are then periodically removed with the settled sludge during the period of sludge wasting in the decant phase. Each macrofloc particle contains an external aerobic zone and an internal anoxic zone even during the aeration phase, and this means that both nitrification and denitrification occur simultaneously within the same reactor zone and cycle phase, reducing both the required reactor volume and overall cycle time when compared to traditional ASP or SBR processes.

Whilst the te-cycTM process is well established with over 600 reference plants with capacities ranging from 200 to 1.2 million population equivalents, Te-Tech Process Solutions have developed a range of off-site manufactured standard modular plants in response to a growing demand for a more sustainable solution to achieve tightening phosphorus consents on small to medium sized treatment works.

The in-house manufacture and assembly of the package plants drives quality, programme reductions, cost efficiencies and minimisation of exposure to risks associated with on-site installation activities. As a single stage modular treatment solution, te-cycTM provides a compact and resilient solution for small treatment works in AMP 7.

mike.froom@te-tech.co.uk

Tel: 023 8235 1600

www.te-tech.co.uk