Every day, over 50 million premises receive good quality water, sanitation, and drainage services thanks to the UK’s fantastic framework of utility engineers, and more than £130 billion has been invested in maintaining and improving assets and services over the past 30 years.

RVT Group understand that people living or working near improvement works need to be protected from the risk of contaminated water and adverse odours. We also know that site operatives must be protected when working in confined conditions with dangerous gases such as ammonia, chlorine, radon and phosphorous in the atmosphere. Finding effective solutions for your ventilation challenges can be tough, but RVT’s superior equipment and highly trained technical experts are on hand to ensure you have the most effective solution for your site.

Ventex® Ventilation Solutions

RVT’s Ventex® Ventilation solutions can provide fresh air supply to displace and dilute contaminated air. The Ventex® range can also be used to create negative or positive pressure to keep contaminants and odours contained. From shafts, tunnels and pipelines, to contact tanks, reservoirs and CSO’s, we understand the challenges you may face when trying to maintain good air quality. In over 25 years of experience, we have found our Ventex® centrifugal fans are best suited to the ventilation challenges faced by the water and sewage industries.

Our Ventex® Solutions in Action

During AMP6, several of our powerful centrifugal fans provided ventilation during maintenance at the King George V Reservoir. Cleaning was required in two of the reservoir’s underground tunnels, but dangerous levels of ammonia were creating a highly dangerous atmosphere for site operatives.

After a detailed site assessment, RVT consultants proposed using several Ventex® 450S Centrifugal Fans. The 450S is a powerful centrifugal fan, designed to provide high pressure airflow through long duct runs. Therefore, it is ideal for forced ventilation or extraction from confined areas such as shafts, tunnels and sewers.

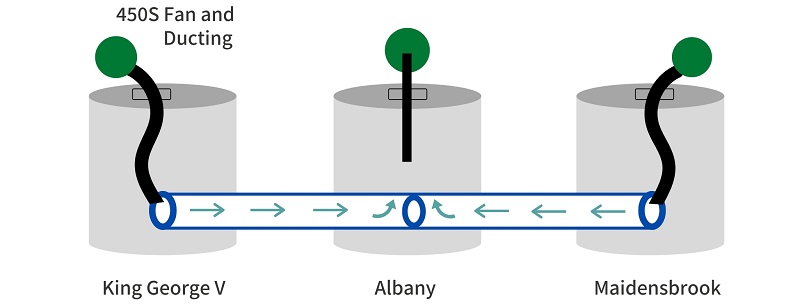

The tunnels that required cleaning ran from the King George V Reservoir to Albany and from Albany to Maidensbrook. At all three locations are large underground shafts leading down into the tunnels, accessible via manholes. To achieve effective ventilation of the tunnels, a 450S Ventex® centrifugal fan was placed at the shafts of both the King George V Reservoir and Maidensbrook. Flexible duct runs were then fed through the manholes of the shafts, allowing these fans to vent in fresh air at each end of the tunnels. The contaminated air then exited through the manhole at the top of the Albany central shaft using forced extraction, making these tunnels a safe environment for site operatives.

RVT Group – Your One Stop Shop

In addition to our powerful ventilation solutions, we also provide a range of other expert hazard control equipment, including monitoring, noise control and confined space equipment.

RVT’s Soundex® acoustic solutions are ideal for controlling noise during site works, over-pumping and similar processes. Our high-quality noise barriers not only offer excellent sound attenuation but have also been tested by third party approval bodies for fire resistance, water resistance, scaffolding compliance and wind loadings.

Our Monitex® Range includes gas, dust, noise and vibration monitors, allowing you to check that exposure limits are not being breached throughout your project with access to detailed real-time data.

RVT also provide a wide range of specialist confined space equipment to keep your site operatives safe, including gas detectors, breathing apparatus, harnesses, lanyards and rescue and resuscitation equipment.

If you would like to know more about how RVT Group can protect your site operatives, please visit www.rvtgroup.co.uk, or call Silas Melvin on 0808 178 3286 and ask for our special water industry rates!