An innovative non-contact radar sensing technology from SICK is opening up the prospect of robust and reliable real-time monitoring of fluid levels in demanding water industry applications.

SICK LFR SicWave is a fluid level sensor with maximum range of 30m that represents a breakthrough in technology for continuous measurement of levels in water and wastewater treatment tanks and vessels.

Non-Contact Breakthrough

The SICK SicWave uses higher-frequency 80 gigahertz free-space radar to overcome the limitations of lower-frequency radar sensors or mechanical devices to achieve precision continuous level measurement.

Where previously operators have settled for switch point level indication or have been defeated by the challenges of using non-contact sensors in harsh environments, the narrowly-focused microwave pulses of the SICK SicWave sensors penetrate through vapour and material build-up to output highly-accurate results.

Darren Pratt, SICK’s UK product manager for industrial instrumentation explains:

“Anyone who needs to measure the levels of liquids in storage tanks will understand the frustrations that can be caused when trying to achieve a reliable level measurement using a non-contact optical or radar principle when the signal is disrupted by the presence of vapour or build-up of residue, or by other obstructions in the vessel.

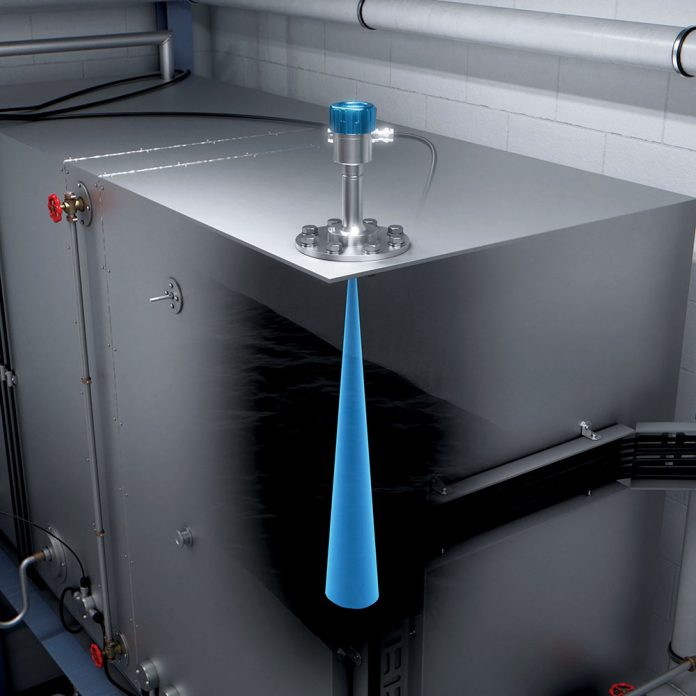

“When positioned at the top of a tank, a SICK SicWave sensor sends a highly-focused narrow beam of microwave radar pulses and uses the time-of-flight principle to return a high-quality signal even at exceptionally long ranges or extreme temperatures and pressures.”

High Availability

The SICK LFR SicWave 80 GHz free-space radar sensors are a thousand times more sensitive than previous-generation 26 GHz radar technologies, ensuring high availability in even the most challenging environments with minimal maintenance requirements. The narrow field of view also avoids the potential for false signals caused by deposits on walls or by other obstructions inside the vessel and ensures focused alignment to enable simple and rapid set-up.

Remote set-up and interrogation of the sensors is straightforward, either using the on-board WPAN interface to a smartphone or tablet via Bluetooth or through standard HART communication, which also enables easy integration with higher level controls and diagnostic systems. The sensors have a standard 4 – 20 mA output, enabling signals to be monitored and displayed on a dashboard in a cloud environment using IIoT gateways such as SICK’s Telematic Data Collector.

The SICK SicWave LFR fluid level sensors come in a wide range of space-saving antenna designs, versatile flange or thread process connections, and a range of application-specific mounting options. The robust IP66/IP67 plastic or aluminium housings are ready for harsh industrial environments with an IP69 stainless steel housing available for use in hygienic environments. Variants with ATEX or IEC Ex certification are also available for use in explosive environments.

The SICK LFR SicWave measures fluid levels reliability between -196°C and +200°C, and process pressures between -1 and 25 bar.

“The 80 GHz free space radar technology, when combined with the wide-ranging application versatility of these sensors, promises to be a true gamechanger for many operators working in demanding water treatment environments,” concludes Darren Pratt. “The LFR SicWave also offers a really useful non-contact solution for measuring the level of liquids in Intermediate Bulk Containers, a common requirement in the water industry. It can even do this through the plastic material of the IBC.”

The SICK LFR SicWave free space radar sensors are complemented by SICK’s range of process instrumentation for level, temperature and pressure measurement.

For more information about the Sick SicWave LFR and LBR free-space radar sensors, please contact Andrea Hornby on 01727 831121 or email andrea.hornby@sick.co.uk

www.sick.co.uk