For the UK water sector, construction not only requires an understanding of topography but of the natural ecology, resources, the built environment and socioeconomic factors. As we face increased demand for and emphasis on investment in improved and new infrastructure, the way we build must be redrawn with the help of the ‘kit-of-parts approach’, says Dale Sinclair, Head of Digital Innovation, WSP.

For centuries, humans have constructed buildings, for all their uses, and the way we create these structures is cemented into our culture.

While construction has historically created fantastic solutions to unique sites, each with its own challenging topography and planning restrictions, the way we construct remains slow, both in design and delivery, leading to variable quality and rising costs.

This is where the kit-of-parts approach comes in, a design and construction methodology that uses offsite manufacturing and advanced digital technologies to create efficient, sustainable, and customisable solutions.

As a sector, the water industry is under pressure to keep costs down and build a water infrastructure that is efficient and resilient to climate disasters, and this needs to be done at speed.

The decision engine

To mobilise a kit-of-parts effectively needs a shift from project to programme thinking. This involves looking at conceiving and creating the kit-of-parts on a project and then making it deployable across a programme of projects.

In many respects, the foundation of a kit-of-parts methodology is a decision engine. That is, capturing the decisions made on a project and the reasons why they were made. By understanding the “why”, we begin to take a programme approach creating a catalogue of repeatable decisions, or decision engines, able to be applied to different projects across the country. For the water sector, this could mean standardising designs for treatment plants, pumping stations, and pipeline networks, ensuring that proven solutions are applied efficiently across multiple locations rather than reinventing them for each project.

For example, the UK government’s goal to build 1.5 million new homes over the next five years will significantly impact the water sector, with each development requiring scalable solutions for water supply, drainage, and wastewater treatment. By applying a programme-level approach, modular infrastructure can be rapidly deployed to meet growing demand while ensuring consistency in quality and efficiency.

Offsite manufacture

This programme-level thinking can transform the way we manufacture. By using large, repeatable offsite components on projects such as wastewater treatment sites, storage facilities, or pipeline infrastructure, we can reduce the number of these components and the deliveries made to the site, significantly reducing project duration.

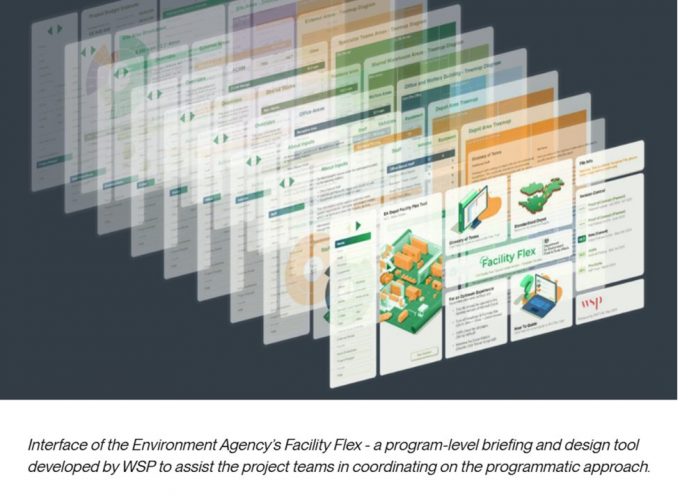

The Environment Agency is already applying this thinking; building a series of depots across England with repeatable pre-manufactured, it is projected to reduce project time by 40% while enabling customisation at scale.

In water infrastructure, this approach is particularly beneficial for modular treatment plants, prefabricated pumping stations, and repeatable flood defence structures. These solutions allow for rapid deployment, reduce the environmental impact of construction, and enhance resilience against climate-related challenges such as extreme weather events and rising demand.

Once we have a set of fixed, repeatable components, projects can then be tailored to specific site requirements to strengthen quality.

Sustainability and social value

In using programme-level thinking, there are huge benefits to sustainability and social value. Removing unnecessary decision-making enables us to focus on continuous improvement to design our operational and embodied carbon and improve performance. Offsite manufacturing minimises the environmental impact of construction activities at the site; waste in a factory environment is roughly 2% compared to up to 30% on-site. It also means that we can support a circular economy when it comes to our water infrastructure; sites can be more easily adapted for future use and demand. This is especially important in response to climate disasters.

Moving construction activity from site to factory enables the industry to draw on a wider pool of multi-skilled talent and create new jobs all while making use of robotics and automation to address skills shortages.

As regulatory pressures increase and demand grows for resilient, cost-effective water infrastructure, adopting a kit-of-parts approach offers a practical solution. By embedding this methodology, the sector can accelerate delivery, enhance quality, and ensure future-ready infrastructure that meets both current and future needs.