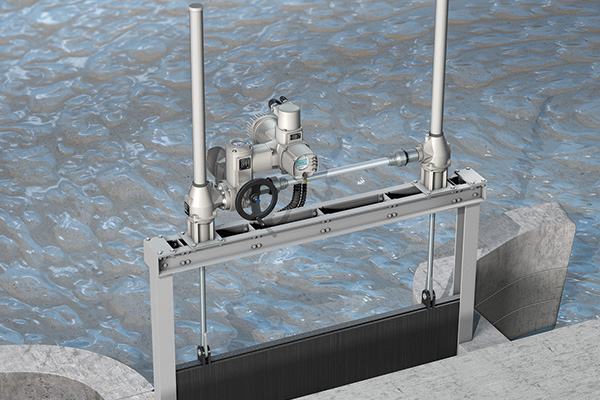

AUMA Actuators Limited has introduced a new battery backup system engineered to maintain actuator operation during mains power loss. The solution is designed to meet the stringent reliability and performance requirements of critical industries, including water treatment, energy, and process control.

AUMA’s innovative, bespoke backup system employs sealed lead-acid battery technology, selected for its proven durability, strong depth-of-discharge (DoD) performance, and cost-to-performance advantage compared with lithium-based alternatives. The solution delivers a five-year service life, with batteries that are end-user replaceable.

John Callow, Technical Solutions Specialist, AUMA Actuators Limited, commented: “Our new battery backup solution has been developed with reliability and user confidence in mind. We’ve combined proven lead-acid technology with automated diagnostics and oversized capacity to ensure that our customers’ actuators continue to operate even during prolonged power outages. For critical applications, this means greater resilience, reduced downtime, and complete peace of mind.”

Each unit is integrated with a Battery Management System (BMS), which regulates charging cycles, prevents overcharging, and prolongs service life. The BMS includes a self-diagnostic test function, automatically executed every 24 hours. This test cycle, lasting 30 seconds, evaluates charge retention and internal condition, ensuring that operators receive early detection of potential degradation. This feature makes the system effectively maintenance- free, eliminating the need for manual inspections and extending operational life.

The new system offers oversized battery capacity housed in a glass reinforced plastic (GRP) cabinet, providing greater energy reserves than actuator-mounted solutions and confidence, as well as addressing variable outage durations. This configuration allows operators to specify runtime support across a range of downtime scenarios, from short-duration disturbances to extended outages.

The backup solution is engineered for straightforward integration into existing actuator infrastructure. Technicians can complete installation independently, or operators may opt for AUMA’s dedicated field service engineers to perform commissioning and integration. Safety has also been prioritised in the design: the lead-acid chemistry avoids the thermal runaway risks associated with lithium-ion systems, while the BMS provides continuous charging regulation to protect against overvoltage and heat build-up.

The system is supplied with a 12-month panel warranty, alongside a five-year guarantee on the batteries, underlining AUMA’s confidence in long-term reliability. In addition, the recyclability of the lead-acid batteries ensures compliance with industry sustainability standards, supporting organisations pursuing circular economy and decarbonisation goals.

John Callow concludes: “AUMA’s new battery backup solution delivers a technically robust safeguard for critical flow control applications where actuator availability is paramount by combining oversized, steel-enclosed capacity with automated self-diagnostics, proven battery chemistry, and maintenance-free operation.”

For more information, visit www.auma.co.uk