Improved coagulation, Lower final effluent COD, Lower suspended solids.

Industrial wastewater treatment often involves an activated sludge plant as part of the treatment process. However due to the nature of an industrial production process, the effluent sent to the treatment plant can sometimes vary in quality.

Unlike municipal wastewater treatment, an industrial effluent treatment plant can often be deficient in a range of nutrients. The main macronutrients, nitrogen and phosphorus, are usually added to these processes to balance the microbial nutrition. It is often the case however, that the trace element micronutrients and iron, in particular, are often forgotten.

This situation is sometimes typical in the paper industry, where although plants often run adequately, they are usually in need of optimisation due to changing effluent quality. Varying flows and COD/BOD loads along with micronutrient deficiencies tend to give rise to periodic problems at the activated sludge plant. Problems such as filamentous bulking, pin flocs, poor floc structure, turbid effluent or just a general “unhealthy” feel to the plant.

This is the situation that was occurring at the activated sludge plant discussed below.

This paper manufacturer produces a wide range of coated papers and boards for the packaging industry. The effluent plant was continually struggling to give a reasonable final effluent quality.

Although within consent, the plant suffered periodic setbacks, which could take up to several weeks to recover. Reseeding with fresh sludge from a nearby plant was an occasional occurrence.

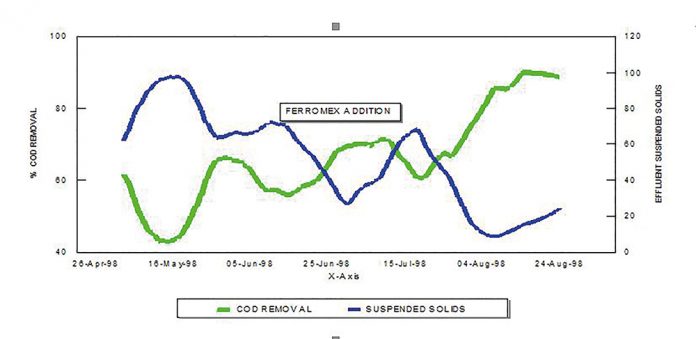

Improvements to the quality of the primary effluent were undertaken but had a limited effect. As a further step in optimizing the process, Ferromex® 621 was applied to the activated sludge plant. Within a few weeks of application there was a significant improvement to the values of the consented parameters, with the focus being on COD and suspended solids. The final effluent suspended solids concentration reduced to well below consented limits and remained there. The COD removal rate dramatically improved, from an average of only 50%, to over 80% and BOD discharge to the river was very low. These improvements in COD removal and the reduction in final effluent suspended solids, due to the addition of Ferromex® 621, can be seen on the graph above.

Ferromex® 621 provides a balanced supply of trace elements for the activated sludge enabling the bacterial biomass to be more resistant to periodic process parameter variations. Recovery, in these cases, has been found to be quicker.

In addition to this, the inorganic iron component of the product provides a gentle coagulating action, which assists with the more efficient, natural settlement of the biomass in the final clarification stage.

The effluent plant manager noted “Ferromex® 621 has proved far more effective than any previous additives and has greatly improved plant stability.”

For further information on the Ferromex® range of products contact OMEX Environmental Ltd

Tel: +44(0)1553 770092