England and Wales water companies wishing to meet their PR19 Outcome Delivery Incentives during AMP7, need on average to reduce Leakage by 16% and Supply Interruptions by 41% no later than 2025.

In previous AMP periods water companies have often focused on smaller diameter District Metered Area (DMA) pipelines for leak detection and fixes. However, leaks from the larger distribution trunk main pipelines that principally supply water abstracted from the environment, have the potential for far more significant individual leaks.

However, you can’t effectively manage Leakage if you’re reliant on outdated or unproven network flow models rather than real-time dynamic data from in-situ flow meters. And more often than not, there’s no existing flow measurement where you need it.

Potable drinking water extracted from rivers, aquifer bore holes, reservoirs, etc is generally delivered via large diameter pipes carrying the Distribution Input (DI) raw water to the treatment plant where the water is treated and disinfected. The water is then pumped to the local distribution system through a network of large diameter trunk mains before splitting into smaller diameter DMA pipes.

Conventionally, large diameter trunk main pipes equated to very expensive inline flow measuring systems comprising large diameter electro-magnetic flowmeters, bypass lengths of pipeline, expensive large bore isolation valves and substantial civil costs to create underground chambers of sufficient size to house everything. Such projects can rapidly escalate to hundreds of thousands of pounds.

Fortunately , there is a cost-effective alternative.

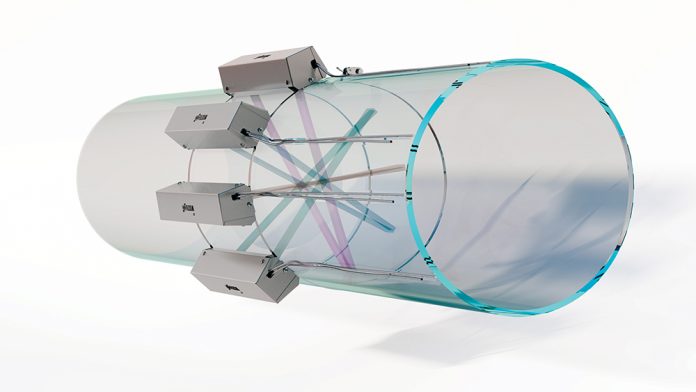

Not only are FLEXIM FLUXUS WD Series clamp-on ultrasonic flow meters significantly lower cost than large diameter inline meters, but they can also be retrofitted during normal operation, without any supply interruption, nor the substantial additional cost of civil engineering work and pipework modification.

Water companies utilising reservoir water sources are frequently incapable of shutting off supply to the network to enable replacement work to take place for failed inline meters. In these circumstances the retrofit of a FLEXIM WD meter is a truly easy retrofit. Transducers sized appropriate to the pipe type and condition, are securely fixed to the pipe with 316ss fittings; so secure you can stand on them without decoupling transducers from the pipe.

IP68 transducers are also available for reservoir pipes in flooded chambers.

Extensive large diameter trunk main networks can be responsible for potentially catastrophic leakage events. Network modelling can assist, but nothing is better than real-time dynamic metering at point of flow. FLEXIM Fluxus WD Series meters are installed on significant water aqueduct pipelines supplying raw water to treatment works at some of the UK’s most important cities. Once fitted, with no measuring parts within the flow stream, the meters are virtually maintenance-free and can simply be checked via verification software at prescribed intervals.

For one major UK water operator, Distribution Input (DI) flow within 2 pipes, 1.8m and 1.5m diameter was of such critical importance to a significant conurbation, it was decided that the improved uncertainty of 4-channel metering per pipe was warranted for peace-of-mind and optimum leakage detection.

For further information on how FLEXIM can deliver highly accurate metering at optimum cost and without any supply interruption contact: sales@flexim.co.uk | 01606 781 420 | www.flexim.co.uk