In this issue of the Water Industry Journal, we speak to Paul Barter, Principal Process Engineer at Hydro International, about his experiences of the Chemical Investigations Programme Phase 2 (CIP2) and suggestions for improvements for future programmes.

Measuring up CIP2

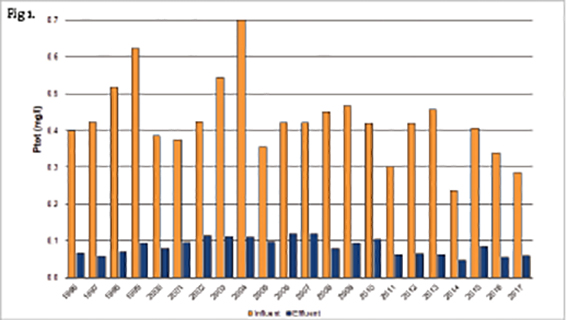

“The CIP2 trials are an industry-wide initiative looking at how we can best go about removing phosphorus from wastewater. As part of the investigations, the UK water industry has been undertaking a number of pilots and full-scale trials using the latest technologies to see what is achievable.

“The findings have been helpful in some respects, providing useful data about what certain technologies can achieve – but the investigations have also had shortcomings. First and foremost, by only testing new technologies a perception has been created that these are the only technologies which are endorsed for phosphorus removal. This means existing technologies with a tried and tested removal performance in the field have been and will continue to be overlooked.

Changing the goal posts

“Some existing technologies are already achieving the goals set for phosphorus removal, but because phosphorus removal targets have been tightened relatively recently, not all existing technology has been fully optimised, showing how effective it could become.

“It would have been interesting to see what established technologies could achieve when pitted against new ones, thereby providing more meaningful insights for the industry. After all, what matters is effective phosphorus removal, not the novelty of the technology being used. The relatively narrow scope of the current investigations means the industry has been short-changed.

Untapped potential

“The untapped potential of tried and tested technology is yet to be explored. Looking ahead to CIP3, I would suggest that existing technologies are included, so that we can see precisely what levels of phosphorus removal they can reach.

“There has also been a mismatch in terms of how some of the trials have been conducted, specifically which datasets were used and how they were interpreted – meaning not all of the trials are comparable. Data interpretation should have been the same across the board – but not all of the water companies were working to the same protocol, so they failed to achieve uniformity of results.

“In addition, for a new system to be tested by a single company, does not result in a robust trial from which the industry can extrapolate – it simply doesn’t give a sufficiently in-depth picture of what a system is capable. Ideally, each system should have been tested by more than one or two companies.

The problem of pollutants

“Another shortcoming in my view is that the investigations have focused solely on phosphorus removal and haven’t looked at this in the context of our broader efforts to remove additional pollutants, like ammonia and nitrogen.

“We mustn’t neglect other pollutants. Looking to CIP3, I would hope it would examine pharmaceutical discharges, for example. Some established technologies, like aerated sand filters, remove a broader range of pollutants, meaning they are both effective and cost-efficient, meeting more requirements.

Rethinking chemical usage

“How chemicals are fed into the process stream will affect the amount of removals obtained, whatever technology is utilised. Chemicals need to be well-mixed and spread evenly to be able to deliver optimal pollutant removals.

“I would also like to see, as part of CIP3, investigation into dosing methods which will provide insight and guidance for operators to ensure that dosing is optimised and removal targets are met without excessive/overuse of chemicals.

Efficient use of finite resources

“From an environmental perspective, phosphorus is a finite resource that, like all natural resources, will be used up over time. Given that it is utilised in so many products, we need to be thinking about how we can use less of it and look more closely at how phosphorus can be both recovered and recycled.

“Society has to come to terms with the idea of making and using products from recovered phosphorus, people tend to be uncomfortable with that, but we have to get over it. We also need to embrace resource efficiency with regards to the water itself – recycling and reusing water to a greater extent. From a municipal perspective, this could involve a greater proportion of drinking water quality being derived from recycled water. For industrial sites, improved treatment processes can lead to more closed loop systems, helping to reduce both water supply and sewerage obligations.

What next for the water industry?

“The water industry could use existing technologies to better effect,” explains Paul, “see how they measure up against new technologies and look at phosphorus removal in the context of our efforts to remove a broader range of pollutants. In addition, the industry should ensure that the chemicals we utilise are employed more efficiently so that we don’t use more than is absolutely necessary.”

For more information about wastewater phosphorus removal technologies visit:

www.hydro-int.com/hydro-p-removal