Geomembranes are essential components in various water infrastructure projects, including water treatment plants, reservoirs, and canals.

However, these critical barriers are susceptible to damage, which can lead to significant water loss, environmental contamination, and operational disruptions. To mitigate these risks, advanced leak detection systems are crucial. This can lead to significant environmental and financial consequences. To mitigate these risks, our permanent Electric Leak Location (ELL) systems are a reliable solution for ensuring and maintaining the integrity of geomembrane installations.

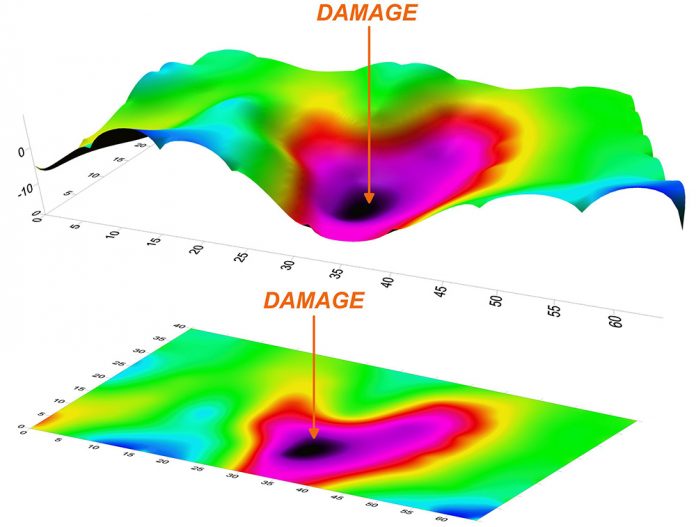

Permanent (ELL) systems are designed to safeguard the integrity of geomembrane installations. By continuously monitoring the geomembrane, our systems can detect and locate leaks early, ensuring the long-term performance of critical infrastructure. ELL systems employ a network of sensors installed beneath, above or between geomembranes. These sensors continuously monitor the watertightness of the geomembrane, using electrical signal that indicate leaks and their position. By analysing the data collected from these sensors, our engineers can assess the integrity of the geomembrane at any stage, from installation to the end of operational life (min. 30 years). ELL systems offer both offline and online monitoring options. Offline monitoring involves periodic inspections by technicians, while online systems continuously collect and analyse data, triggering alarms in case of a leaks. This real-time monitoring ensures prompt detection and timely remediation.

By adopting a ‘Zero Leak Philosophy’ and utilising ELL, the water and waste industries can significantly enhance the protection of their assets and the environment. With 35 years of experience, Sensor is at the forefront of this technology. This article pinpoints this phenomenal method which we have developed, installed and monitored for the last 27 years. We have successfully applied this ELL system in 44 countries and over 50 million m2 of liner.

Ensuring Long-Term Reliability

A critical factor in the success of permanent ELL systems is the durability of their components. Sensors, cables, and connectors must withstand the harsh conditions of the subsurface environment for decades. To ensure the longevity of these

systems, rigorous testing and quality control measures are essential.

In Europe, the BAM Certification sets a high standard for product durability, requiring components to withstand at least 30 years of burial in hazardous conditions. By adhering to these stringent standards, we can guarantee the long-term performance of our ELL systems.

Key Steps in Implementing a Permanent ELL System:

1. Installation and Commissioning: The system is carefully installed, ensuring proper sensor placement and cable routing. Rigorous testing is conducted to verify functionality and calibration.

2. Initial Leak Detection: Before operation, the system identifies initial defects in the geomembrane for repair. This process also involves other techniques like arc testing, to ensure a leak-free start.

3. Long-Term Monitoring: Once the system is fully operational, it continuously monitors the geomembrane for leaks. Data is collected and analyzed to identify and address potential issues promptly. Offline and online options are available, offline being cheaper with no site power needs.

Case Study: Large-Scale Containment Tank in South America

A significant challenge arose during the construction of a 55,000m2 containment tank in South America. The tank, designed to store demineralized water, required a robust monitoring system to ensure the integrity of its double-liner system. A permanent ELL system was installed to monitor the geomembranes continuously. The system’s advanced features, including a Local Alarm Module (LAM) and remote monitoring capabilities, enabled early detection of potential issues. The system successfully detected and located multiple leaks during the initial filling phase, preventing significant environmental damage and operational disruption.

By investing in our permanent ELL systems, industries can safeguard their assets, protect the environment, and achieve long-term sustainability. As technology continues to advance, ELL systems will play an increasingly vital role in ensuring the integrity of critical infrastructure.