Launched last May at IFAT 2018 in Munich, Germany, the patent-pending Proteus BOD real-time biochemical oxygen demand (BOD) monitoring platform enables treatment works to measure the quantity of reactive organic matter in real time. Michael Oswell of Proteus Instruments explains how the monitor works and gives an overview of its significance in achieving operational efficiencies in water resource recovery facilities.

Advanced monitoring improves understanding of organic matter dynamics

The organic load of wastewater treatment works varies markedly in concentration and composition across both space and time as it responds to different treatment processes or stages, such as raw water to final effluent, and population demand.

A laboratory bioassay dating back to 1912, biochemical oxygen demand (BOD) is still the industry standard for measuring the quantity of reactive organic matter. The BOD test, also known as BOD5, is used to accurately measure dissolved oxygen at the beginning and end of a 5-day period in which the sample is held in dark, incubated conditions. BOD is currently used to assess the efficiency of wastewater treatment works to ensure that processes are optimized for cost and energy consumption. It also measures whether or not final effluents are below regulatory thresholds or below levels that would cause environmental damage. However, this testing method has a major drawback: the time lag that exists between sample collection and results. This delay prohibits real-time alerts and control that could provide substantial cost savings to the industry and valuable environmental protection.

Having accepted that traditional BOD measurements are, by default, simply a snapshot of what happened 5 days ago and that environmental protection and damage may or may not have happened, it is worth considering some of the other issues of the BOD5 sampling test.

Toxic substances, such as metals, can inhibit microbial respiration, and laboratory conditions fail to recreate natural processes. The results are therefore not always simple to interpret, as a low value can be due to high organic content that is not readily degraded or whose degradation is inhibited by toxins.

Even in certified laboratories, accuracy can be as low as 30 percent uncertainty—and that figure only applies to the analytical component, which does not involve all of the potential issues involved with the sampling and transportation process. As BOD5 is inherently imprecise and has a high minimum detection limit, it cannot be used reliably to monitor clean or uncontaminated river water. Additionally, there is the risk of operator exposure to biohazards during sample collection and the potential for accidents around open water during the sampling process. Finally, in an age in which compliance, risk mitigation, and optimization are key, the BOD5 test is clearly not fit for purpose, even when real-time monitoring and process control is not required.

Solutions beyond BOD5

While BOD5 testing comes with several limitations, other options exist for monitoring the reactive organic load in real time via technologies including via SCADA, RS-232, SDI-12, and Modbus, among others. These technologies provide numerous advantages in a variety of applications including:

- Wastewater treatment aeration optimization

- River pollution monitoring

- Pollution source tracing surveys

- Bathing water monitoring

- Borehole monitoring

- Industrial effluent discharge

- Combined sewage overflow (CSO) event detection

- Monitoring clean water systems for coliform ingress

- Agricultural runoff.

Additionally, fluorescence spectroscopy provides the ability to monitor in real time using a selective and sensitive optical technique enabling in situ, real-time measurement of dissolved organic matter. Molecules absorb light of a specific wavelength, and orbiting electrons are excited to a higher energy state. The electrons then emit light of a specific wavelength to return to the base state.

The use of fluorescence spectroscopy as a technique for the rapid assessment of organic matter quality and quantity in wastewater is an effective tool for monitoring treatment processes and assessing efficiency. Studies have highlighted that tryptophan-like fluorescence (TLF), a fluorescence signal associated with amino acids, proteins, and phenols, is strongly related to BOD concentration across the treatment process.

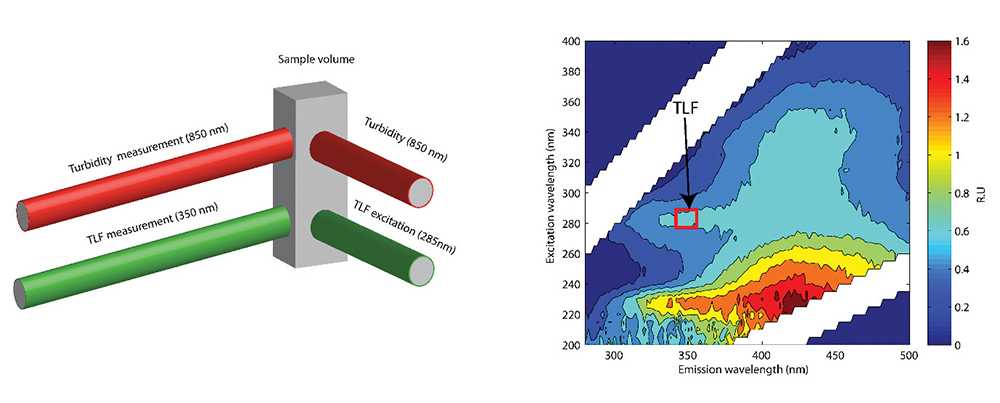

The TLF peak is generally associated with excitation at approximately 280 nanometers (nm) and emission at approximately 350 nm, as shown by the red box in Figure 1 on the Excitation Emission Matrix (EEM). However, analysis of TLF has, until recently, required sample collection and transport to a laboratory for analysis on spectrofluorometers, which are expensive, large and power-hungry.

The Proteus BOD monitoring platform

Since 2013, Proteus Instruments and Birmingham University have developed and rigorously tested the Proteus BOD, a fluorescence-based, real-time platform that monitors BOD and chemical oxygen demand (COD). By combining a miniaturized LED-based TLF sensor, thermistor, and turbidity sensor, the Proteus BOD is able to provide users with highly accurate and reliable real-time BOD/COD measurements and when fitted with a second, optional, fluorometer the Proteus BOD can be configured to measure Dissolved Oxygen Demand (DOC) and Total Organic Carbon (TOC).

The sensor is embedded with robust correction algorithms to account for signal interference associated with temperature and turbidity variability. The Proteus BOD comes equipped with a standard factory BOD/COD and/or DOC/TOC calibration derived from installations across a diverse range of applications that can be customized for specific monitoring sites to optimize accuracy. The sensor platform also has an integrated wiper for cleaning all optical windows to eradicate fouling in demanding environments, thus reducing the need for user intervention and ensuring a stable baseline for long-term deployments.

The Proteus BOD is “low drift” allowing accuracy to be maintained for long periods only requiring calibration every 6-12 months. It is deployable into a wide range of environments including inlets, effluents, reservoirs, and boreholes. Its modular design enables a wide range of additional parameters to be recorded concurrently, (e.g. temperature, turbidity, pH, conductivity, optical DO, TOC, DOC, chlorophyll a, ORP, ammonia and many others) and it is highly sensitive to detect very low concentrations for use in clean water and wastewater systems.

In addition to industrial applications, research organizations are using the sensor package to improve their understanding of reactive organic matter dynamics. Researchers at the Birmingham Institute of Forest Research (BIFOR) in the United Kingdom, for example, purchased two units for a long-term monitoring project and are pleased with the sensor stability and accuracy. BIFOR Research Fellow Dr. Phillip Blaen says, “The low maintenance requirements due to the integrated wiper and infrequent calibration requirements make the Proteus ideal for long-term monitoring of organic matter.”

The patent-pending Proteus BOD is a versatile sensing unit that can provide real-time BOD data alongside traditional parameters, thus incorporating environmental sensing needs into a single, easily deployable, low-maintenance monitoring platform. The comprehensive savings associated with the Proteus BOD include reduced laboratory costs, reduced likelihood of fines and reputational damage, energy savings through process optimization, and additional BOD sampling cost savings. The Proteus BOD has the potential to change the way reactive organic matter loads are monitored globally while improving reliability, accuracy and resolution.