Phosphorus management is one of the key issues in water treatment with the Water Industry National Environment Programme (WINEP) and the Water Framework Directive driving tighter consent standards in AMP7. Here Michael Froom, Business Development Director at Veolia Water Technologies discusses the options for meeting these requirements and how water companies can look to futureproof their capital investments.

The detrimental effects of phosphorus on the natural environment are well documented and understood but have posed an increasing challenge as farming has intensified over recent decades. As such, tightened phosphorus consent standards across many regions of the UK will mean this is a key focus in the next Asset Management Period (AMP) up to 2025.

Although it can be tempting to focus on the current requirements, it is important to consider the long-term effects. As a regulated industry, there is a tendency to concentrate on immediate obligations and so choosing the lowest cost solution that meets the requirements of the current AMP is often seen as the best option. However, this is not always the most cost-effective approach in the long term.

While there are a number of options for phosphorus removal from wastewater, an increasingly common approach to achieving low consent standards is chemical treatment. This technique uses a metal salt, most commonly iron, to precipitate orthophosphate. The Ferric phosphate formed is separated from the water in a settlement tank or through the use of a tertiary solids capture process such as a disc or sand filter. However, not all solutions offer the same level of performance and so it is important to look carefully at the information provided by manufacturers to ensure the technology can achieve the desired removal requirements.

One of the strengths of chemical water clarification as a long-term solution is that the process can be adjusted without the need for further capital investment. The dosing of metal salts can be altered to manage changing phosphorus levels in the water or meet lower consent standards without impacting the clarification stage efficiency and operation. This flexibility will be limited for some of the separation technologies proposed so careful selection of an effective and adaptable solution that surpasses the current standards can allow changing consents and needs to be met at a lower capital investment. This in turn allows funding to be spent more innovatively in the next AMP to meet evolving needs.

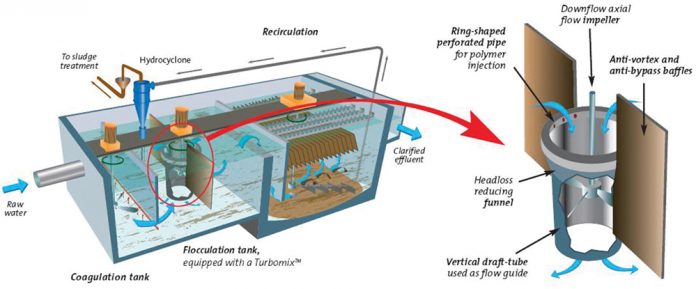

Another important aspect of futureproofing that is sometimes overlooked is making the optimum use of space. The scarcity and increasingly intensive use of land in certain areas of the UK means that often the site cannot be expanded. As such, solutions that offer the necessary capacity with a compact footprint are valuable. This allows new equipment to be installed to meet future standards or demand without the need for total replacement of the existing systems. For example, Veolia’s Actiflo clarifier solution utilises microsand to ballast the chemical flocs, significantly increasing the settling velocity of the particles. This delivers very short retention times and a more compact design. In fact, the footprint of an Actiflo system is as much as 40 times smaller than conventional clarifier systems.

Another well-established method for removing phosphorus from water is filtration, with the most common technologies being disc, drum or sand filters. For many applications, disc filters, which utilise a fine media mesh mounted on a number of rotating discs, have several advantages. These units will commonly have a smaller footprint compared with other options as they allow the surface area of the filters to be maximised for a given space. For example, Veolia’s Hydrotech DiscFilters provide a higher level of filtration for a smaller footprint than many standard drum or disc filters. This technology also offers a flexible and modular solution with a comparatively low TOTEX – the total expenditure combining CAPEX and OPEX.

Furthermore, where lower levels of phosphorus are required it is possible to combine disc filters with a chemical approach by adding metal salts upstream of the filter. The formation of phosphate solids allows the extraction of dissolved phosphorus to achieve the necessary standard.

Finally, when considering their long-term goals, water companies should also look at evolving their approach, and going beyond simply removing phosphorus to implement phosphorus recovery processes.

Phosphorus is a finite resource with no artificial substitute and many vital applications as an agricultural fertiliser and animal feed. Phosphorus recovery technology involves the creation of struvite crystals (magnesium ammonium phosphate) by adding magnesium salts in highly concentrated orthophosphate waste water as liquor from the sludge dewatering. The struvite is then separated from the water ready to be transported for reuse, most commonly in fertiliser production. As most of the phosphorus in the water comes from human activity this recycling creates a circular economy in phosphorus use and allows optimum use of natural resources. It also helps improve the return on investment by turning the cost of sludge disposal into revenue generated from the sale of the struvite.

Phosphorus management is an important part of protecting the local environment and a priority in AMP7. However, when building and upgrading facilities to meet these goals it is important to consider the longer-term cost implications. Water treatment solutions providers can offer the support and guidance needed to ensure the best technologies are selected for the particular application.

To find out more about Veolia Water Technologies’ range of solutions visit

www.veoliawatertechnologies.co.uk.