Through Industry 4.0 technology, SEEPEX has refined its range of progressive cavity pumps to introduce the pump generation of the future, today. The unique patented SCT AutoAdjust technology in combination with SEEPEX digital solutions enables remote adjustment to restore pump performance at the optimal operating point without onsite manual intervention.

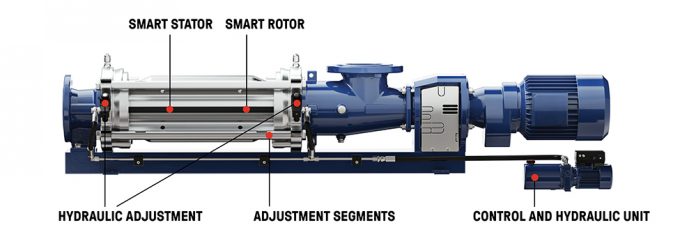

SCT AutoAdjust is the next evolutionary step of Smart Conveying Technology (SCT), an ease of maintenance design launched over 10 years ago to simplify and speed up maintenance removing the need for dismantling the suction or discharge pipework. The design of SCT AutoAdjust maintains the same design features of SCT while incorporating hydraulic controls to restore and maintain pump performance.

Remote Adjustment with One Click

The integration of SEEPEX digital solutions with SCT AutoAdjust enables such adjustment to be made remotely from the pump, through the SEEPEX Pump Monitor and SEEPEX Connected Services. This reduces the need for onsite manual intervention and time-consuming trips to pumps installed in remote, inaccessible locations or large complex sites.

All with just one click and without the need for special tools or replacement of components, SCT AutoAdjust enables the pump’s efficiency to be restored remotely and adapt to changes in process conditions. This translates into significantly improved uptime, longer service life of components, reduced need for spare parts and lower life-cycle costs.

The Power of Digital

SEEPEX digital solutions incorporating the SEEPEX Pump Monitor and Connected Services enable predictive and forward planned maintenance to increase resilience, process and asset uptime, and facilitate on time spare parts availability.

The Pump Monitor transforms the progressive cavity pump into an intelligent field device that constantly monitors the status and performance, and immediately reports deviations to the user.

Advanced analytics provided by the cloud-based Connected Services, combined with SEEPEX application expertise, deliver process optimisation, improved equipment and plant efficiency, creating previously unimagined potential for increased equipment availability.

SCT AutoAdjust offers the ability to maintain both pump performance and efficiency remotely. The predictive and forward planned maintenance afforded by monitoring and advanced analytics increases uptime and spare parts availability. Maintenance becomes easy and simple and unplanned downtime is reduced.

Summary of Benefits

- Ability to restore pump performance and efficiency remotely

- Predictive maintenance through monitoring and advanced analytics

- Forward planned maintenance

- Reduced reactive maintenance

- Increased uptime