By now pretty much everyone in the water industry knows all about horizontal directional drilling (HDD), or at least thinks they do. According to David Furlong though, there is still a lot of misinformation and misunderstandings, and he should know – he was one of the first engineers to introduce trenchless techniques to the UK.

That was in the mid-1980’s, and nearly 35 years later David is still actively pushing the benefits of no-dig techniques through his company Mole Utilities, and still disappointed when he finds himself having to explain the basics of HDD and moling to smart, experienced engineers and main contractors.

As a teenager working for a UK energy company, David spent a lot of time digging up roads to install gas pipes. This was hard, heavy work, and when he heard about a ‘new’ method of pipe installation called moling he immediately saw the potential. Of course, these techniques weren’t really new, they were already widely in use across Europe and the US, but the UK utilities sector in the early 1980’s wasn’t known for being at the forefront of innovative thinking! Having seen the light, David decided to go it alone and set up his first business, Mole Machine in 1989.

The leading provider of moling technology at the time was Essig, who had developed the idea in 1966, and that’s who provided David with his first equipment. David thinks that he was the first person to use moling commercially for water pipe replacements in the UK, and it coincided with a rapid increase in interest in the technology. At the time, the realistic capabilities of impact moles (or “earth rockets”, as they were sometimes called at the time, which we think sounds much cooler) was limited and for bigger jobs engineers turned to the HDD equipment and techniques that had been developed by the oil and gas industry. As far as we know, the first utilities installation using HDD was in 1971 in California, to install 600ft (182m) of 4” (1016mm) steel pipe. The industry rapidly expanded, particularly in the US, with the number of operational rigs manufactured and sold increasing from 12 in 1984 to 2,000 in 1995. By 2011 it was estimated that there were more than 32,000 HDD rigs in operation worldwide, since when the huge increase in interest in the technique from China will only have driven the number upwards.

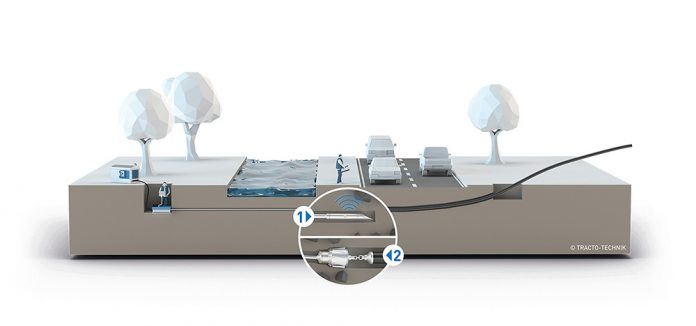

Once again, adoption in the UK remained behind the curve – Mole were amongst the first to use HDD rigs, in 1990, but the relentless technological improvements in the equipment did slowly drive uptake. Tracto-Technik being a longstanding Mole supplier who continuously develop their equipment and innovate. By 2000, impact moles were stronger, faster and more reliable, whilst HDD became increasingly automated, more powerful and much more compact without compromising performance. It is in this latter area of compact HDD that Mole have focussed, as it better fits their expertise and customer base, and they now specialise in small footprint-rigs that are perfect for minimal-impact utilities installations in any area, even those with limited access.

Looking back over the past three decades of trenchless installations, David reflected that “it’s not unusual for new techniques to take time to be adopted, but that seems to have been extreme for HDD. We’ve always been behind other countries in using trenchless to minimise disruption, scarring and environmental impact, and it really is time that we not only caught up, but start to take the lead”.

David is clearly still passionate about changing this thinking.

“Every time I see a road being trenched for utilities, it makes me furious! I know there’s always an economic consideration, but we should be thinking about costs more broadly. Sure, it might be cheaper per metre to trench than drill, although even that’s not always true, but when you take into account the additional costs of road closures, reinstatement and waste disposal, those numbers change quickly. And as for the other ‘hidden costs’ to society caused by the chaos of digging up roads and the misery it causes…it’s frustrating.”

The bright side of this history of slow adoption is that those who ‘see the light’, like David, seem to become passionate advocates of the technology. Experts think that demand in the UK is likely to increase, driven by environmental pressures, creaking infrastructure and increasing population density, and point to anecdotal evidence that a ‘tipping point’ may have been reached in awareness of the options, with many contracts now specifying trenchless techniques from the start. We can’t wait to see what direction the industry takes over the next thirty-five years.