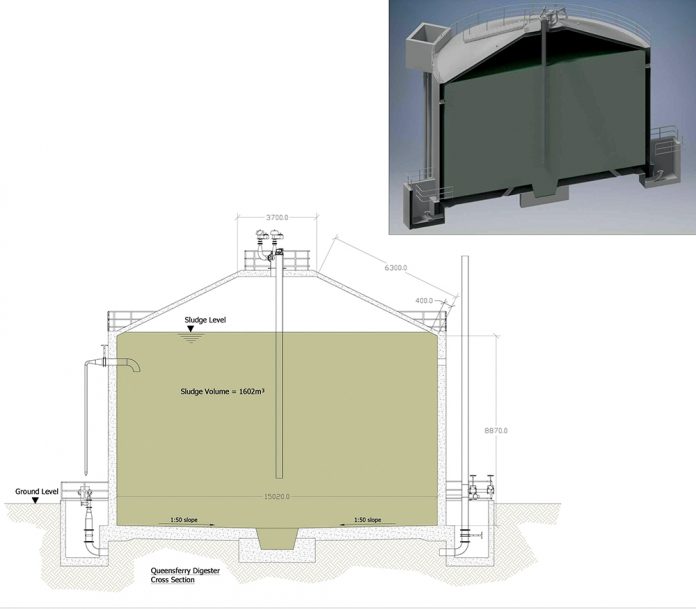

In 2016 Marches Biogas was requested by Welsh Water to undertake a detailed review of the Anaerobic Digestion Plant at Queensferry to determine the condition of the plant, the associated process equipment and the feasibility of extending the safe and efficient operation of the plant for at least another ten years. The concrete digesters alone had been in near-continuous operation for over 30 years so a detailed internal and external inspection was essential as part of the review.

Marches Biogas carried out a detailed HAZOP study and design review in order to highlight the potential hazards and improvements the plant and process could benefit from. During the initial review and design period Marches Biogas worked very closely with the Welsh Water Capital Delivery Team as well the Queensferry WWTW Operational Team to ensure all operational issues were incorporated into the final scope.

Marches Biogas was awarded a contract to carry out the works and to provide Principal Contractor duties. It was a requirement by Welsh Water that the AD plant continued to operate at as close to full sludge throughput as possible and on contract award the AD plant was handed over to Marches Biogas to ensure this requirement was fulfilled.

During Digester No.1 decommissioning and isolation period, the digester biogas headspace was purged with nitrogen before the forced air ventilation was installed in order to manage the residual methane and hydrogen sulphide levels to within safe limits.

With assistance from Celvac Ltd, the digester was then emptied, degritted and cleaned out using a recirculating flush out method.

Once the digester was empty and safe entry could be made a drone survey was carried out, the drone was piloted by one of Marches Biogas engineers within the confined space.

On completion of the reviews and further meetings with all the stakeholders, the recommended upgrades to the plant began to take place. As a result of the drone inspection the digester was scaffolded internally so that the biogas headspace could be prepared, repaired and treated with a protective coating, in order to prevent any further degradation.

The existing confined biogas mixing system was replaced with the Marches Biogas’ tried and tested stainless steel unconfined biogas mixing system through a sequential rotary valve.

A bespoke degrit system was designed and installed, this is based on creating a very high flow rate for a short period of time local to the lowest point in the digester. Initial trials show it is easy to operate and very successful at removing grit from the digesters while in full operation.

Extensive works were carried out to improve the efficiency and operation of the digester feed system through the redesigning of the feed pipework arrangement; the digester heating system through the addition of a hot water diversion valve and simple auto control through the new PLC and SCADA system. Significant works were carried out to improve the flow of biogas throughout the plant and to the eventual consumers being CHP, biogas boilers and surplus gas burner. The works carried out on the biogas system improved the overall safety, both in terms of protection against foaming and further improvements within the boiler house to better comply with IGEM/UP/16.

On completion of the works on digester No.1 warm sludge was screened and transferred directly from digester No.2 reducing significantly the time to commission the refurbished digester. The requirement of Welsh Water to continue to operate the plant at full sludge throughput was met during the entire contract and not until the works were completed and the operator training was given did Marches Biogas hand the plant back to the client.

Following the refurbishment and upgrades the digesters are now able to cope far better with the varying operational demands of the Waste Water Treatment Works, with the digesters operating efficiently, resulting is consistent solids reduction and increased biogas yield. The final stage is for Marches Biogas to carry out a lithium trace test on the plant to determine the effectiveness of the mixing of the digesters and the effective operational volume.

The overall refurbishment and installation has been a success and throughout the project there has been a very close and professional working relationship between all involved. The successful culmination of this project has resulted in Marches Biogas being awarded a contract to carry out a similar project at the Welsh Water anaerobic digestion plant at Eign, Hereford.