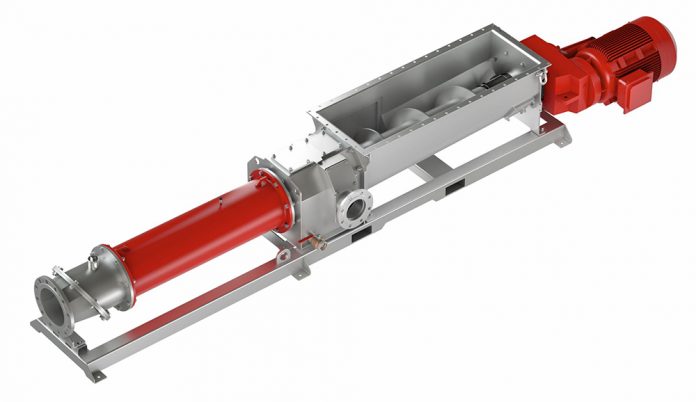

Leading biogas machinery manufacturer, Vogelsang, has unveiled its latest biogas feed system, the MixXPump.

Compact and flat, it is designed to be easily integrated into existing feed systems, which may be restricted with their original machinery layouts. It also uses Vogelsang’s HiCone progressive cavity pump, which is designed for a significantly longer life between changing parts.

Jonathan Gutteridge, managing director for Vogelsang, said: “With the MixXPump, we are adding a compact solid matter feeding system to our portfolio for feedstock such as maize silage or dry animal feed. Thanks to its flat design, the MixXPump can fit into existing AD plants more easily compared with other feed systems currently on the market.”

“The feed system is a key function in the process of an AD plant and has a big influence on its gas yield and energy requirements, so it pays to get it right,” added Jonathan. “Generally, the more thoroughly the feedstock is processed, the higher the gas yield. Our range of feed systems gives plant operators the choice to select the perfect system for their needs and enjoy trouble-free fermentation.”

HiCone: the pump at the heart of the MixXPump

The central component of the MixXPump is the HiCone conical progressive cavity pump. It conveys the previously prepared and mashed solid matter as a suspension into the digesters. The conical rotor-stator geometry of the HiCone makes it possible to compensate for signs of wear on the conveying elements through precise readjustment. This can dramatically reduce stoppage time and replacement parts.

If the rotor and stator do need to be replaced, the downtime can be reduced to just a few hours due to Vogelsang’s QuickService concept. This design has simplified the replacement of the parts of Vogelsang pumps and equipment, so the plant’s fermentation process is not disrupted.