Water. It’s found everywhere and is essential to human life. Each person requires at least 20 to 50 litres of clean, safe water a day for drinking, cooking, and personal hygiene and that’s why the World Health Organization (WHO) and national agencies have drinking water quality standards that specify the acceptable microbial, chemical, and radiological characteristics of safe drinking water.

Microbes, chemicals and natural pollutants can make water unsafe to drink, can cause water-related diseases. Water companies provide essential services to treat and deliver safe drinking water and to remove wastewater and dispose of it with minimal impact on the environment. If water sources are not protected, or are unexpectedly contaminated for any reason, the quality of drinking water suffers. That’s why millions of tests are conducted every year to guarantee the best possible quality of water for consumers.

When we talk about water quality, we look at the physical (chemical) attributes of water as well as its visual properties: consumers expect their water to look clean as well as taste nice and the requirements for water quality are changing with time, whether driven by legislation or by customer perception.

While water is distributed through an infrastructure that collects, treats, stores and delivers water between the source to the consumer, water sits within a wide range of pipes made from different materials, that are joined together with fittings and valves to form the distribution network. The time water spends in the system and its subsequent degradation through exposure to materials, influences the quality of water customers receive.

A lot of work goes into addressing these matters at the beginning of the design and construction of a new pipeline. However, with many new infill developments located in vacant brownfield areas where land has been reclaimed from a former commercial or industrial use, the risk of soil contamination affecting drinking water quality is real and it is increasingly common to use pipes with barrier properties to prevent permeation of contaminants into the water supply.

It may be worth mentioning that barrier pipes form a system and it is expected that fittings used to join barrier pipes will themselves sustain the barrier so that the whole system prevents permeation of substances likely to affect human health. The UK is the only country to have set standards in which this continuation of the barrier is specified.

Examples of full barrier pipe systems from Radius Systems include a polyethylene and aluminium pipe under the Puriton tradename which, together with their Redman branded barrier fittings, offers a full ‘barrier system’. These types of barrier pipe systems are used as standard in developments on reclaimed land and increasingly for kerbside renewal works by utilities, where the long term run-off from vehicle discharges leaching from the verge, give rise to similar contamination concerns. These barrier solutions ensure the health implications of drinking water is given priority and that the water quality is maintained.

For many developments, including rehabilitation works, it is now the case that polyethylene pipe will be used for the bulk of pipeline systems within the water distribution network. The long coil lengths reduce the occurrence of joints, and where joints are formed there are methods of reliably welding the pipes to form leak-tight joints. Fewer welded joints reduce the risk of infiltration in surge events where organic matter is drawn into the network and may create a biological hazard.

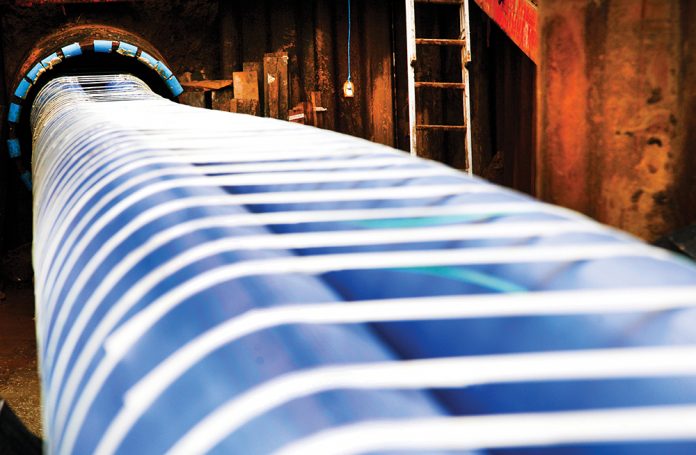

Polyethylene pipes are often used for insertion inside existing metallic pipe assets at the end of their operating lifetime, which with more informed network management supporting downsizing and use of slip lining techniques, moves water through the network faster. This, in turn, reduces the aged water volume, the risks of microbiological growth and improves quality. Simple solutions providing good news.

Other less intrusive means are available when it comes to managing existing assets in differing conditions. For iron pipes or asbestos cement pipes for example, where the pipe remains in good condition, quality can be improved by spray coating the pipe surface internally. Well-known techniques in the UK like polymeric spray coatings, are preferred lining techniques (over cement mortar lining for example) to maintain the quality of water distributed.

Two-part spray solutions using polyurethane or polyurea, are commonly specified to deliver a barrier layer between the water and the original host pipe to improve water quality. Examples from Radius Subterra include the Subcote offerings, which have same day return of supply to minimise the loss of service time, and which raise water quality without compromising capacity in the network. The increased coating thicknesses that can be achieved from the high build nature of these materials, means that it is possible to address certain defect sizes to reduce leakage at the same time. Used extensively worldwide, as well as within the UK, this material enables better asset management.

If the pipe structure is degraded, then polyethylene pipes can be specified for the replacement of the asset, using interactive or fully structural close-fit linings. These options which reduce leakage and improve water quality, will maximise flow capacity and will restore the integrity of the pipeline, whilst minimising the engineering works necessary for installing the replacement pipe.

Polyethylene materials, in particular, are specified for drinking water applications worldwide, supporting a global industry which has provided the resources and expertise to ensure the performance of these materials, and the pipe systems they support, is continually improving. Innovative work and continuous improvement that underpin reliable asset performance for well in excess of 100 years and verifiable high water quality for the end consumer.